“The winner has clean hands” – Playful trainings on good WASH practices in Ethiopian industrial parks

Industrial Park (IP) development in Ethiopia was initiated as part of the government transformation goal to industrialization of the country. IPs are intended to increase the contribution of industries to the national GDP and stimulate export and foreign direct investment. The Ethiopian Industrial Parks Development Corporation (IPDC) was established in 2014 as an engine of rapid industrialization that nurtures manufacturing industries, accelerates economic transformation and promotes and attracts both domestic and foreign investors. Currently, there are 13 IPs across the country, creating more than 83,000 jobs and generating a revenue of over $850 million so far.

Improving workers’ knowledge on sanitation and hygiene

One of the challenges, among many, that IPs are faced with during Covid-19 is the safety of their workers. In March 2020, when the first case of Covid-19 was reported in Ethiopia, many IP workers feared contracting the virus because of their close and interacting work environment. As the World Health Organization recommends, washing hands properly is an effective method to reduce infection rates. In addition to providing personal protective equipment (PPE), awareness raising on the importance of proper hygiene was one of the priority topics taken to ensure the safety of workers.

The nation’s first IP Bole Lemi, located in Addis Ababa, started operating in 2014. It specializes in the production of textile, garments, leather, and leather products; most of it destined for export. Currently, there are 20 shades rented by different investors from India, China, and South Korea.

Even though currently Covid-19 is a less discussed topic, it is still a global challenge. In addition, 60 to 80% of communicable diseases in Ethiopia are attributed to poor water, sanitation and hygiene (WASH) conditions. The relevance of proper WASH, therefore, extends far beyond reducing the infection rate of Covid-19, also improving the general health conditions of workers who are the driving engines of IPs.

Make personal hygiene a priority

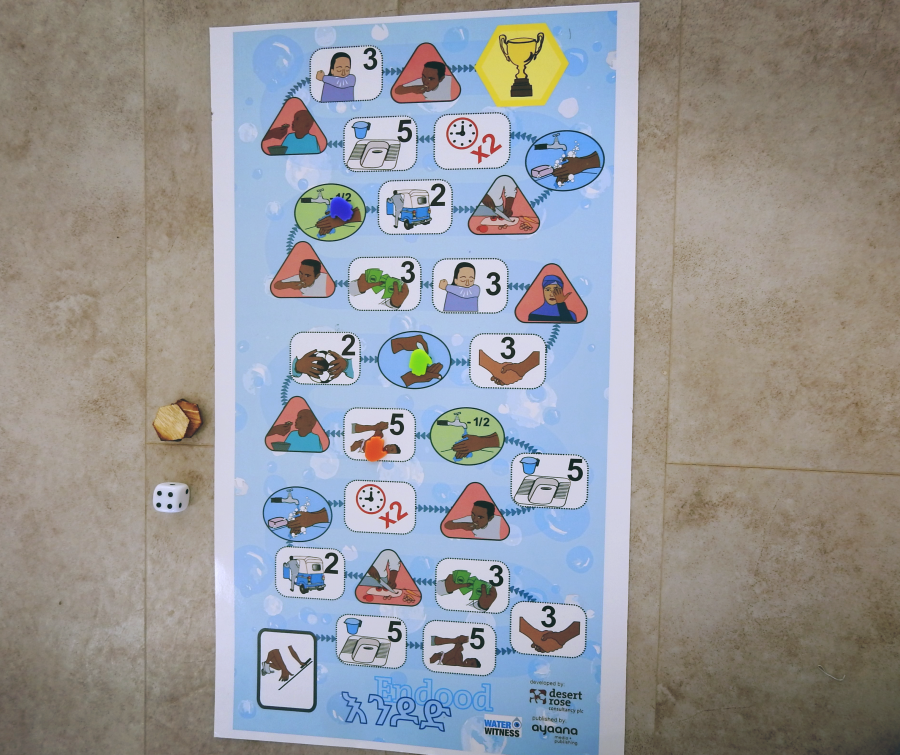

To raise awareness for the importance of WASH for the wellbeing of workers and their families, training of trainers (TOT) on proper hygiene was provided to workers at the Bole Lemi IP. By playing an interactive game, composed of various potential sources of contamination and improper personal hygiene, participants learn how to avoid or counteract these along the way: in the end, to win one needs to have clean hands.

The training is designed for trainees to easily understand how daily activities could potentially transmit diseases to others, putting them at risk. After the game, participants reflected on their change of perspective about applying personal hygiene both at the workplace and at home. They agreed that easy measures can make a significant difference if awareness for their importance is anchored in a group.

The trainees, who are diverse professionals from different production shades will take the game to their shades and their homes, playing it with their co-workers or families. The trainer from Water Witness International highlighted feedback from former trainees who played “Endood” with their families and colleagues, during breaks or at the dinner table. In this way, the knowledge about the importance of proper hygiene spreads beyond the group of trainees.

Safe workspaces and awareness for hygiene measures are essential to improve working conditions in IPs across Ethiopia, both during the ongoing Covid-19 pandemic as well as to counteract many types of communicable diseases stemming from poor WASH conditions.